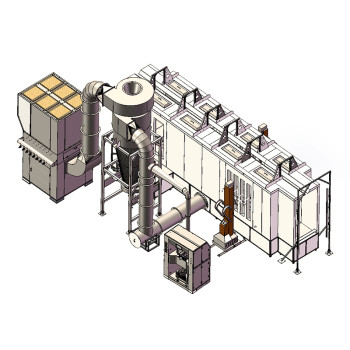

Efficient Recycling Automatic Powder Coating Booth & Reciprocating System

- group name

- Automatic Powder Coating Machine

- Min Order

- 1 piece

- brand name

- COLO powder coating machine

- model

- COLO-Automatic Spraying System

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram

- update time

- Tue, 24 Feb 2026 18:56:41 GMT

Paramtents

Delivery Time 30 Working Days

Shipping By Sea

Application Metal Finishing Industry

Packging & Delivery

-

Min Order1 piece

Briefing

This system suitable for high recovery efficiency or fast color change demands in automatic powder coating application line.

Detailed

Efficient Recycling Automatic Powder Coating System

Application

The Automatic Powder Coating System includes:

COLO-191S automatic powder coating gun,

COLO-2200D powder coating reicprocator,

COLO-PP plastic automatic powder spray booth,

COLO-6200 powder feed center,

suitable for high recovery efficiency or fast color change demands in automatic powder coating application line.

PP Plastic Automatic Powder Spray Booth

Excellent Features

1. Booth material is made anti-static engineering plastic, which is non-stick of powders, reduces powder waste and improve efficiency.

2. Mono cyclone achieves recycling efficiency up to 98%, a great saving of powders, a quick cleaning takes around 15 minutes.

3. With the discharge device of "large-diameter cyclone separator + after filter unit" makes the least powder accumulation and the most environmental-friendly emission.

4. There's air clean system continuously transports over sprayed powder from the booth floor, quickly recycling it back to the powder feed container.

|

Model

|

COLO-PP Booth

|

|

Working Dimension (mm)

|

Width1700 x Depth8600 x Height2100 mm

|

|

Opening Dimension (mm)

|

Width1000 * Heght2100mm

|

Voltage | 380V/220V. customized as local. |

Heating Power | 22kw |

Frequency | 50-60Hz |

Filters | Polyester, 32pcs |

Filter cleaning system | Pneumatic |

Booth Material | Wall:PVC; Floor PVC & Stainless Steel |

Cyclone Material | Stainless Steel |

COLO-191S Automatic Powder Coating Gun System

Excellent Features

1. COLO-191S powder coating unit applies latest DVC technology allows a flexible and accurate setting of all parameters, giving perfect finish with consistent quality.

2. The 100kv spray gun powerfully charge powders delivers high transfer efficiency, increase powder utilization.

3. Air-purge cleanable design for fast, easy cleaning, without gun disassembly.

4. A central control cabinet combines all gun controller for integrated operation, enbales to set parameters only at one host unit to control whole system.

|

Model

|

COLO-191S-A

|

|

Power Range |

220V/110V |

|

Frequency

|

50HZ/60HZ |

Gun Weight | 500g |

|

Temperature range in use |

-10 ℃+50 ℃ |

Rated output voltage | 24VDC |

Input Voltage | 200kv |

Maximum output current | 180Ua(max) |

Maximum output voltage | 0-100KV (adjustable) |

Maximum powder injection | 650g/min |

Polarity | negative (-) |

COLO-2200D Powder Spray Reicprocator

Excellent Features

1. a frequency adjustable motor controlled by PLC, giving more smooth, stable and precise motion.

2. Linear rail guide mechanism, travel through a belt, gives more gentle up-and-down motion with less wear.

3. Heavy-loaded reciprocator with reliability to carry up to 24 pcs powder spray guns

4. Moving speed and stroke can be easily set at the touching screen with 20 storable programs.

5.carries a certain quantity of spray guns for up-and-down motion, delivers excellent uniformity and efficiency of powder coating.

|

Model |

COLO-2200D |

|

Power Supply

|

AC 220V/110V 50-60Hz

|

|

Motor Power

|

1.1kw

|

|

Speed Range

|

0-50m/min(0-0.8m/s)

|

Max. Loading Capacity | 25kgs |

Stroke Length | 1.5m/2m/2.5m |

Standard Size | 850*680*2970mm |

Reciprocator Weight | 295kg |

COLO-6200 Powder Feed Center

Excellent Features

1. Allows directly placing the original powder carton on the funnel, flexible for color changing, no need to clean the powder container.

2. PLC system with touch screen integrates all functions, automatic cleaning of spray guns, powder hoses, injectors during color change, reduce manpower and increase efficiency.

3. Ultrasonic sieving of fresh powders and recovery powders, dissolving and loosening of powder accumulations for even powder flow.

4. A closed powder hopper with a sener will detect the powder position and alarm a signal when a lack of powder.

|

Mode

|

COLO-6200 |

|

Voltage

|

110V/220V, 1Phase (can be customized)

|

|

Total Power

|

100w

|

|

Powder Hopper Size

|

310*240*270mm |

Standard Mesh Size | 80 mesh (on request) |

Ultrasonic frequency | 38kHz |