Automatic Tunnel Powder Coating Booth

- group name

- Automatic Powder Coating Booth

- Min Order

- 1 piece

- brand name

- COLO powder coating machine

- model

- COLO-0825

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram

- update time

- Sun, 08 Mar 2026 14:42:19 GMT

Paramtents

Delivery Time 7-15 Working Days

Shipping By Sea

Application Metal Finishing Industry

Packging & Delivery

-

Min Order1 piece

Briefing

This automatic spray booth with filter is an ideal selection for single color application in automatic powder coating line.

Detailed

Automatic Tunnel Powder Coating Booth

COLO-0825 automatic tunnel powder coating booth designed for fast powder recycle, reliability, precision spray and a mass of parts production application, it is an efficient and economical solution for single color application.

Double stage of filters are directly connected to the booth wall, and the automatic floor cleaning reduces the powder accumulation to a minimum, maximizes powder recycling rate and creates cleaner working condition.

Tunnel powder coating spray booth also called pass through powder booth, the work parts enter the booth through the overhead track from one side opening to another side, during the movement, the parts are powder sprayed. It is suitable for longer or large parts.

Product Details

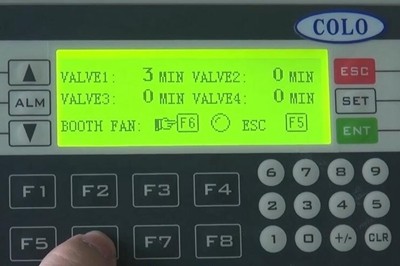

PLC Control

Reliable and easy operation, the PLC panel allows users to stop and start fan motor, set working times of solenoid valves which controls the filter cleaning, also has powder collector lifting switch and emergency stop switch.

Cartridge Filters

An integrated collector module contains 4pcs filters that effectively separates powders from air, provides a dustless working condtion.

The interchangeable filters are easy to replace when changing powder colors.

Fan Motor

5.5kw centrifugal fan motor with strong extraction volume, powerfully draw air through powder booth filter and ehaust the air back to the atmosphere free of powder particulars.

Removable Hopper

A removable powder hopper beneath the filter stage, the released powder will directly drop into the hopper for easy recycling.

Filtered powder is discharged into a hopper beneath the unit which can be taken away for emptying and recycling.

Product Parameters

|

Model |

COLO-0825 |

Type | Automatic Powder Coating Booth |

|

Operating Dimensions |

Width800 * Depth4000 * Height2000 mm

|

|

Overall dimensions |

Width1200mm x Depth2580 x Height5000mm

|

|

Power Supply |

220V/380V, 3Phase, 50-60HZ |

Fan Power | 5.5kw/set, 2 sets total |

Cartridge Filter | 12pcs, Quick-release Type, Polyester Material |

Filter Cleaning | Pneumatic |

Air Consumption | 6000-13000m^3/h |

Product Video