Manual Powder Coat Painting Booth COLO-3212

- group name

- Manual Powder Coating Booth

- Min Order

- 1 piece

- brand name

- COLO powder coating machine

- model

- COLO-3212

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram

- update time

- Wed, 18 Feb 2026 22:03:57 GMT

Paramtents

Delivery Time 7-15 Working Days

Shipping By Sea

Application Metal Finishing Industry

Packging & Delivery

-

Min Order1 piece

Briefing

The powder coating booth is ideal for long thin work parts, such as aluminium profiles, window and door frame, metal plates.

Detailed

Manual Powder Coat Painting Booth COLO-3212

COLO-3212 powder painting booth is designed for the double-sided manual coating, it is the best choice for conveyorized coating applications. The work parts enter the booth through the overhead track from one side opening to another side, during the movement, the parts are powder sprayed, double working stations allows operators to paint both sides of parts simultaneously.

Product Details

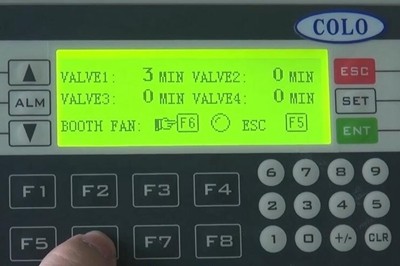

PLC Control

Reliable and easy operation, the PLC panel allows users to stop and start fan motor, set working times of solenoid valves which controls the filter cleaning, also has powder collector lifting switch and emergency stop switch.

Cartridge Filters

Our powder coating booth uses highest quality filters made from 100% polyester, ensure high recycling rate of oversprayed powders and dustless working condition.

The interchangeable filters are easy to replace when changing powder colors.

Fan Motor

3.5kw centrifugal fan motor with strong extraction volume powerfully draw air, a high-performance fan efficiently circulate air with low noise and less energy.

Powerfully draw air through powder booth filter and ehaust the air back to the atmosphere free of powder particulars.

Removable Hopper for Powder Recovery

A removable powder hopper at booth bottom simplifies the utilization of recovery powders.

Filtered powder is discharged into a hopper beneath the unit which can be taken away for emptying and recycling.

Solenoid Valve

Control the pulse-jet cleaning of each filter. The filters are intervally cleaned by releasing accumulated powders controlled via solenoid valve, which extends the filters' lifespans.

Product Parameters

|

Model |

COLO-3212 |

Type | Manual Powder Coating Booth |

|

Operating Dimensions |

Width620 * Depth2920 * Height1500mm

|

|

Overall dimensions |

Width1200 * Depth3000 * Height2030mm

|

|

Power Supply |

220V/380V, 3Phase, 50-60HZ |

Fan Power | 3.5kw |

Cartridge Filter | 6pcs, Quick-release Type, Polyester Material |

Filter Cleaning | Pneumatic |

Product Video