Bridge Type Powder Paint Curing Oven

- group name

- Tunnel Powder Coating Oven

- Min Order

- 1 piece

- brand name

- COLO powder coating machine

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram

- update time

- Sun, 27 Jul 2025 08:14:54 GMT

Paramtents

Oven for Powder Coating

Type tunnel

Voltage 380v

Price custom-made

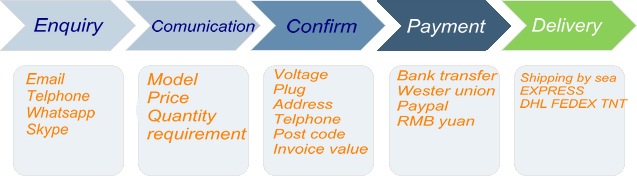

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Mass Production Bridge Type Curing Oven

Bridge bake Oven is one of the important equipment in the coating production lines, its temperature uniformity is an important indicator of the quality assurance coating.

Heating ovens type: radiation, radiation hot air circulation and hot air circulation, etc., according to the production program can be divided by type, such as a single room oven , straight-through curing oven and bridge curing oven .

Hot air circulation oven good insulation, furnace temperature uniformity, less heat loss, has been tested, the furnace temperature is less than ± 3 ° C

Heat hot air circulation system is currently the more common heating method, which uses the principle of conduction convection oven heated to dry and cure the workpiece. Heat according to the specific circumstances of the user's choice: electricity, steam, gas or fuel oil. Heat oven box under the circumstances, may be: at the top, bottom and sides.

heat circulating fan motor is a special high-temperature fan, have a long life, low energy consumption, low noise, small size and so on.