Infrared Gas Heating Powder Coat Oven

- group name

- Infrared Powder Coating Oven

- Min Order

- 1 piece

- brand name

- COLO powder coating machine

- model

- COLO- Infrared Oven

- Nearest port for product export

- NINGBO, SHANGHAI

- Delivery clauses under the trade mode

- FOB, CFR

- Acceptable payment methods

- T/T, L/C, MoneyGram

- update time

- Mon, 16 Feb 2026 14:44:38 GMT

Paramtents

Delivery Time 7-15 Working Days

Shipping By Sea

Application Metal Finishing Industry

Packging & Delivery

-

Min Order1 piece

Briefing

Infrared gas heating powder coat oven is designed to customer requirement of part size, type of coating, conveyor height and line speed.

Detailed

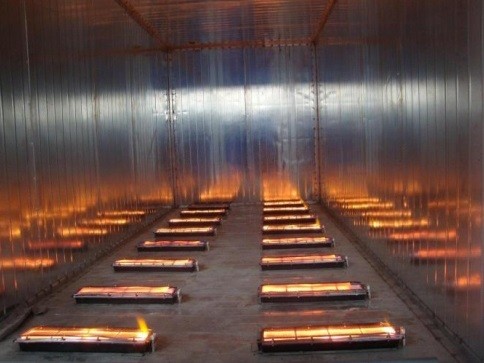

Infrared Gas Heating Powder Coat Oven

Infrared ovens can be gas infrared or electric infrared, it specially designed for curing workparts after powder coating, where the coating chemically reacts with heat to form long molecular cains with high cross-link density, making it tougher and more durable. Increase production ,reduce its natural gas consumption.

Infrared electric heating tube elements or Infrared gas heating elements for your choices.

Built-in track to roll your powder coating racks into the ovens could be ordered together as you required.

Product Details

PLC Controller

The electric controller panel controls all functions, Intelligent temperature control, with alarmdevice, timing, leakage protection, caseenvironmental protection.

Powder Coating Oven Trolley

Standardly equipped with two manual trolleys, an inexpensive solution for transporting heavy workparts by using less force. One internal trolley only move in the chamber of oven across the hall that does not pullete the furnace. The external trolley load the internal trolley for outside transportation.

Circulation Fan

4kw circulation fan circles the hot air to warm the powder coating oven interior, minimizes temperature difference and guarantee uniform-heated chamber. In order to make parts cure with a quality finish with even gloss and consistent color.

Powder Coating Oven Material

Interlayer is 100mm thickness rock wool board, maximize the effect of heat preservation.

Inner wall is 1mm heat-resisting galvanized steel.

Outer wall is anti-rust color steel, durable and long lifespan.

Infrared Gas Burner

1. Energy saving: 95% of energy released in the form of infrared ray, heating the objects directly, saving 20%~30% energy than common gas burner,

2. Environmental protection: CO≤80ppm;NOx≤10ppm;CHx≤50ppm, flameless & smokeless, friendly to environment.

4. Long life:≥11000hr.

Product Parameters

|

Model

|

COLO- Infrared Oven

|

|

Working Dimension (mm)

|

2.4width x 2.2height x 3.2 depth(mm)

|

Overall Dimension (mm) | 2.6 width x 2.4 height x 3.4depth(mm) |

|

Power supply

|

Gas/Diesel/LPG

|

Voltage | 220V/380V(50-60Hz) |

Motor power | 4kw |

Warm-up Time | 15-30min (180°C) |

Temperature stability | < ± 3-5°C |

Temperature max. | 250°C |

Circulation/ Air flow | Vertical ,Variable through holes on the walls |

Ventilation performance | 1000-1677m3/h |

Transportation | Trolley |

Product Video