How cyclone powder booth working

WORKING OF CYCLONE.

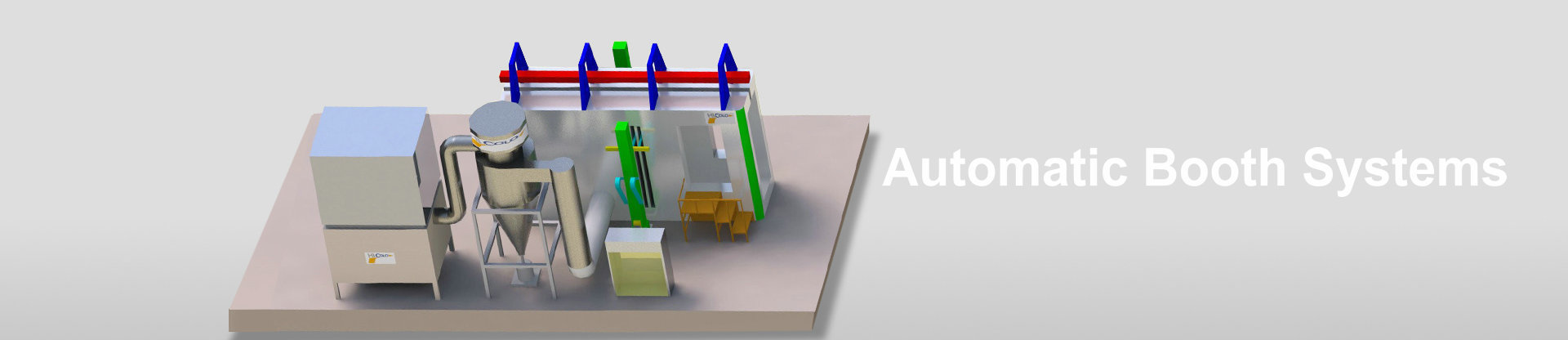

The Hyper Cyclone (one or more) represent the powder overspray recovery system of the powder coating booth (the spray section). The work-pieces, duly jigged are hung on the jigholder in the coating booth (manually or pass on a conveyor line) and sprayed with powder.

A specially designed low-pressure, high capacity air extraction fan sucks air and the powder overspray through the coating booth, through the ducts to the Hyper Cyclone recovery system. Hyper Cyclones have a critical design factor as they are designed and built to work specifically for powder coatings and the normal particle size distribution associated with powder coatings.

The HC entry is such that the powder particles are forced in a cyclonic pattern through the side near the top in the cylinder of the Cyclone. As these powder particles spin round the cylinder in their specific pattern, they descend due to gravity. Horizontal and vertical forcemix on the powder particles ensures that they drop down into the powder bin below the conical part of the cyclone. Virtually clean air is sucked out through the central outlet in the top of the cyclone. More than 95% (often as high as 98-99%) of the powder particles get collected in the powder bin.

Powder particles, referred to as ‘fines’ (very low weight and sized particles) where the horizontal cyclonic and vertical gravitational force-mix do not match also get sucked out with the air. These remaining powder particles are trapped in the after-filters, allowing virtually clean air back to the shop-floor atmosphere.